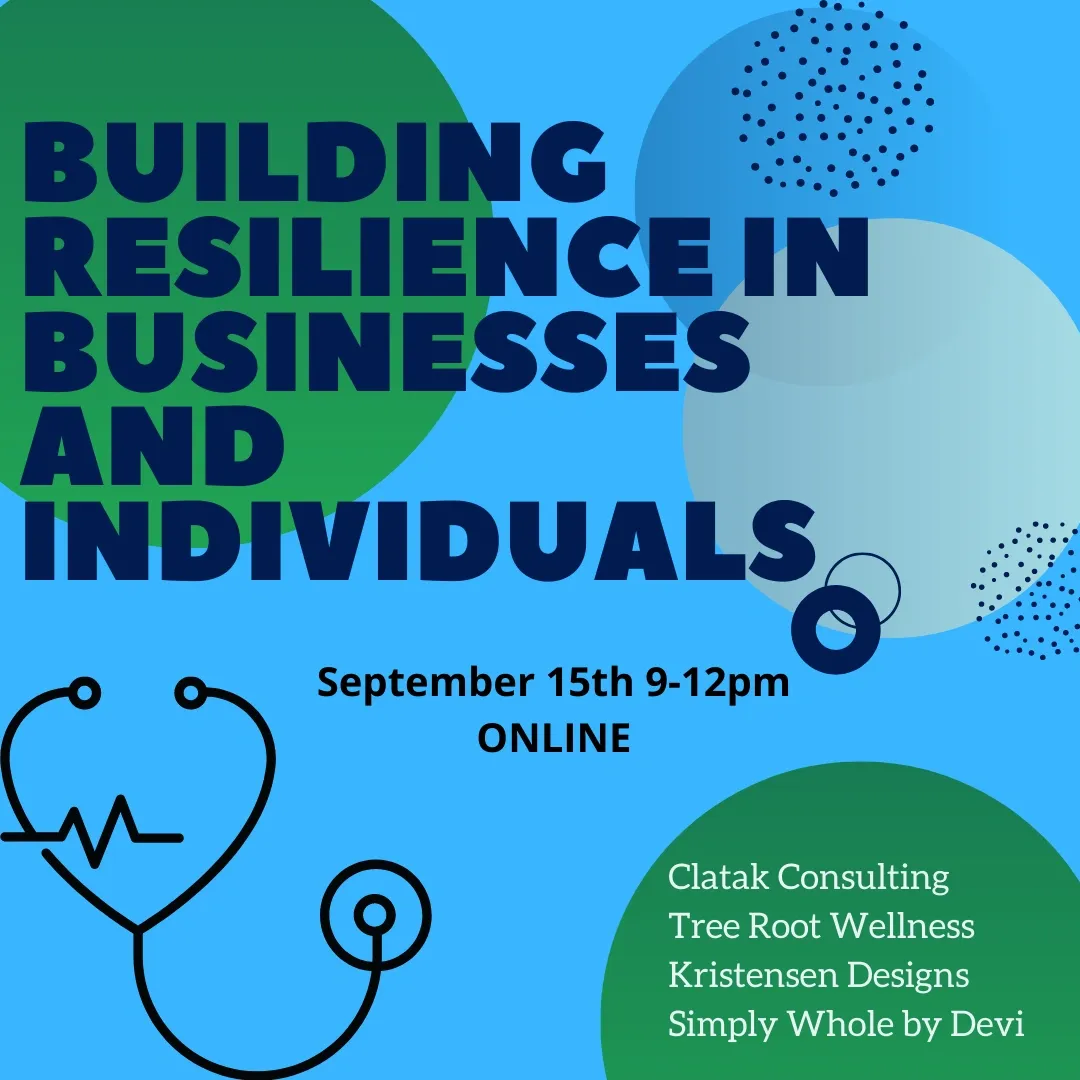

In September 2021 I worked on a webinar explaining how instructional design could relieve stress and increase productivity for business owners. I collaborated with Clatak Consulting. Clatak Consulting is a team-building business so the CEO, Dr. Gwendolyn Avington, and I created a simple scenario to show how both our services could be of use. In this seminar, Dr. Gwendolyn and I focused on resilience in business. We think resilience is about building connections and opening communication. Creating expectations for your employees can build resilience and make your business stronger and more profitable. Below, I summarize what I said during the presentation.

Scenario: Tracy is the Lab Manager for a small clinic laboratory. She works remotely. She has an onsite Medical Technologist to lead the 3 phlebotomists (1 new, 2 experienced) team. Tracy decided to make an onsite visit to the laboratory one day. When she arrived in the phlebotomy area, she almost tripped over several boxes of new supplies. The supplies were blocking the patient entry/exit door. Tracy, realizing this was a patient safety issue, wondered how she might address the issue with the on-site team. Tracy realized the team had their safety training, but it had been a while ago. Kristensen Designs will put together an educational and training component to resolve the patient safety issue.

After talking to Tracy, I’ve learned that supply boxes are blocking entry/exit doors creating a patient safety issue. My first question is why are the employees putting the supply boxes in front of the door? Surely they would know that the boxes could become a safety issue. So there must be an underlying issue I’m not seeing.

After talking to the employees I learn that none of them have been trained on how or where to put the supplies and because there’s a lack of communication between them and management, the 3 phlebotomists have put the boxes in the only place where there’s enough space for such a large amount of supply…the doorway.

We’ve identified the root of the problem for the patient safety issue: lack of training

The employees need to learn how to put the needles for drawing blood safely away. They also need to know where to put the blood bags.

Now we have to figure out what kind of training the employees need. We have 3 choices: Instructor-Led, Virtual Instructor-Led, or eLearning

Since this issue requires hands-on practice, instructor-led training is best.

I speak with the Medical Technologist and Tracy and we’ve decided to ask one of the experienced phlebotomists to be the trainer. As an incentive, Tracy has agreed to give her a raise since this training will add to her workload. The experience phlebotomist agrees to be the trainer.

The next step is designing the Facilitator and Participant Guide.

For the Facilitator Guide, here’s what I’m thinking: It’ll be one 95 minute training. There are 2 trainees and one trainer. Then every new hire will receive this training hereafter. The instructor will show the phlebotomists how to put away fake needles and where to put the blood bags. Then the phlebotomists will each get a chance to practice while asking questions. We’ll give everyone’s brains a break for 5 minutes. Then end the training with the phlebotomists teaching each other and using candy as a motivator for every step correctly completed. The teaching step is very important as it builds camaraderie and cements the learning into one’s long-term memory.

No media like projector, wifi, computer, etc. is necessary and since it’s such a small team they can all gather around the instructor and watch her put the needles and blood bags away. The location will be at the clinic so the location of tools is accurate.

For the Participant Guide, you always want to give the learner something tangible: I designed a graphic to go on the back of the employees’ identification badges. That way if they ever forget, then they can have a cheat sheet that’s easily accessible. We don’t want to shame the learner for not remembering something. We want to make learning as easy as possible.

The last step is figuring out if the training worked. This is arguably the most important step because bad training leads to unskilled workers, wasted time and money. To assess the training I created two objectives:

- Boxes are out of the doorway 100% of the time.

- Blood bags and needles are unpacked in proper places 100% of the time

To check if the employees are meeting these two objectives, I’ll check back in every 3 months and ask the manager if the objectives are being met. For this scenario, we’ll say that the objectives are being met. Therefore, the training was successful.

To view the whole video, click here (it’s about 3hrs long).

0 Comments